Industrial packaging decisions require careful consideration of multiple factors to ensure products reach their destination safely and cost-effectively. When businesses need to specify a cardboard box for their industrial packaging requirements, they must evaluate material properties, dimensions, structural design, and regulatory compliance. The selection process involves understanding load-bearing requirements, environmental conditions during transport, and compatibility with automated packaging systems. Professional procurement teams recognize that the right cardboard box specification can significantly impact shipping costs, product protection, and brand presentation throughout the supply chain.

Material Specifications and Corrugated Construction

Flute Types and Edge Crush Strength

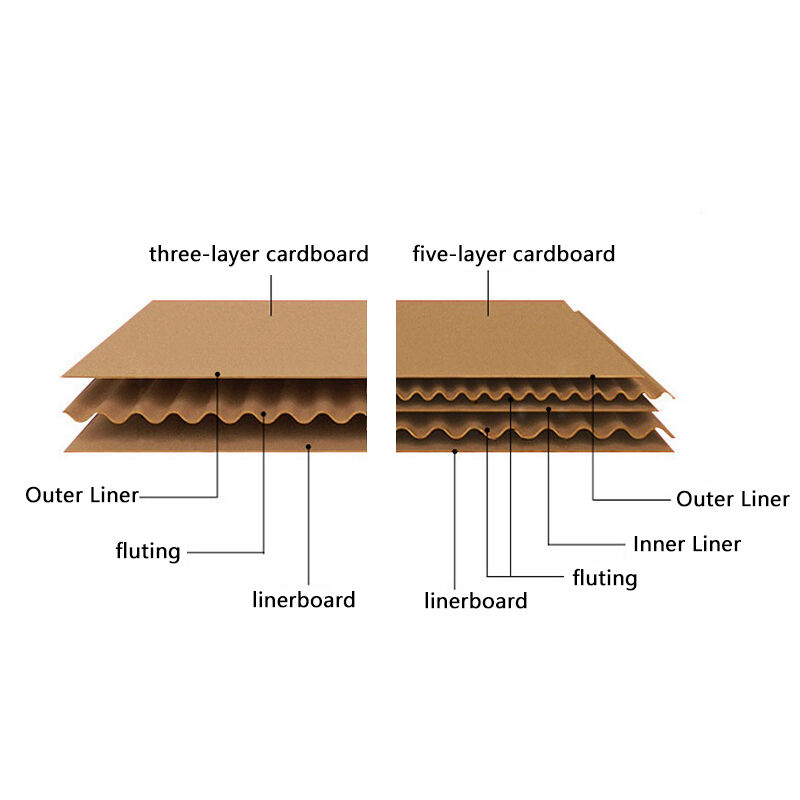

The foundation of any industrial cardboard box specification begins with understanding corrugated flute types and their structural properties. Single wall corrugated board features one fluted layer between two flat sheets, typically suitable for lighter products weighing under 20 pounds. Double wall construction incorporates two fluted layers, providing enhanced strength for medium-weight applications, while triple wall corrugated offers maximum protection for heavy industrial components. Each flute profile, from A-flute to F-flute, delivers different compression strengths and stacking capabilities that directly impact the cardboard box performance in warehouse environments.

Edge crush strength testing determines how much vertical pressure a cardboard box can withstand before structural failure occurs. Industrial buyers typically specify minimum ECT values ranging from 32 ECT for light-duty applications to 71 ECT for heavy-duty industrial packaging. The relationship between box design, flute configuration, and edge crush strength directly influences pallet stacking heights and warehouse storage efficiency. Professional packaging engineers consider these factors when developing cardboard box specifications that meet both protection requirements and logistical constraints.

Burst Strength and Paper Grade Selection

Burst strength measurements indicate the internal pressure a cardboard box can withstand before rupturing, particularly important for products that may expand or contract during transport. Industrial applications often require burst strength values between 125-275 PSI depending on the product characteristics and shipping conditions. The paper grade selection for each layer of corrugated construction affects both strength properties and manufacturing costs. Virgin fiber grades provide maximum strength and printability, while recycled content grades offer environmental benefits and cost savings for appropriate applications.

Moisture resistance becomes critical for cardboard box specifications when products will encounter humid environments or temperature fluctuations during storage and transport. Water-resistant coatings, barrier films, or specialized kraft papers can be integrated into the corrugated structure to maintain box integrity under challenging conditions. Industrial buyers must balance moisture protection requirements against recyclability goals and regulatory compliance standards specific to their industry vertical.

Dimensional Engineering and Load Distribution

Internal Dimensions and Product Fit

Precise dimensional specifications ensure optimal product protection while minimizing material waste and shipping costs. The internal dimensions of a cardboard box must accommodate the product with appropriate cushioning space, typically allowing 1-2 inches of clearance on each side for protective materials. Length, width, and height measurements directly impact shipping classifications and freight calculations, making dimensional optimization a critical cost consideration. Industrial buyers often specify multiple box sizes to accommodate product variations while maintaining packaging efficiency across their product lines.

Load distribution analysis determines how product weight transfers through the cardboard box structure during handling and transport. Corner post reinforcement, internal dividers, and bottom panel construction must be engineered to prevent product shifting and structural collapse. The aspect ratio between box dimensions affects stability during palletizing operations, with square or rectangular configurations typically providing better stacking performance than elongated designs. Professional packaging specifications include detailed drawings showing internal component placement and weight distribution requirements.

Pallet Configuration and Warehouse Compatibility

Standard pallet dimensions drive cardboard box sizing decisions to maximize cube utilization and minimize shipping costs. North American 48x40 inch pallets require box configurations that efficiently fill the pallet footprint without overhang that could compromise stacking stability. European 1200x800 mm pallets necessitate different dimensional approaches to achieve optimal pallet patterns. Industrial buyers specify cardboard box dimensions that create stable interlocking patterns when multiple boxes are palletized together for warehouse storage and transportation.

Automated warehouse systems impose additional constraints on cardboard box specifications, including maximum dimensions for conveyor compatibility and minimum structural rigidity for robotic handling. Pick-and-pack operations require boxes that maintain their shape during high-speed sorting and can withstand vacuum-based handling systems. The integration between cardboard box specifications and warehouse automation capabilities often determines the success of industrial packaging implementations across modern distribution networks.

Printing and Branding Requirements

Graphics Quality and Color Reproduction

Industrial cardboard box specifications increasingly include sophisticated printing requirements to support brand messaging and regulatory compliance. Flexographic printing processes can accommodate up to six colors with registration tolerances suitable for corporate branding and product identification. Digital printing technologies enable variable data printing for serialization, batch tracking, and customized messaging on individual boxes. The surface characteristics of corrugated materials affect print quality, with smoother liner boards providing better graphic reproduction for detailed logos and technical illustrations.

Color consistency across production runs requires careful specification of ink systems and quality control procedures. Industrial applications often demand specific Pantone color matches for brand compliance, necessitating color management protocols throughout the manufacturing process. Pre-print processes can achieve superior graphic quality by printing liner materials before corrugated construction, while post-print applications offer flexibility for shorter runs and variable messaging requirements.

Regulatory Markings and Compliance Information

Industrial packaging regulations require specific markings and compliance information to be prominently displayed on cardboard box surfaces. Hazardous material classifications, handling instructions, and certification marks must be integrated into the overall design layout while maintaining readability and regulatory compliance. International shipping requirements often mandate multiple languages and standardized symbol usage for global supply chain compatibility. The placement of regulatory markings affects both the aesthetic design and functional requirements of industrial cardboard box specifications.

Traceability requirements in regulated industries demand integration of serialization, lot codes, and manufacturing information directly into the cardboard box printing specification. Pharmaceutical, automotive, and food processing applications often require specific data formats and positioning for compliance with track-and-trace regulations. The durability of printed information throughout the supply chain becomes a critical specification parameter to ensure readability at the point of use.

Environmental Considerations and Sustainability

Recycled Content and Circular Economy Integration

Environmental sustainability drives many industrial cardboard box specifications toward higher recycled content levels while maintaining performance requirements. Post-consumer recycled fiber content can range from 30% to 90% depending on strength requirements and end-use applications. The integration of recycled materials affects both the environmental footprint and cost structure of packaging solutions, requiring careful balance between sustainability goals and performance specifications. Circular economy principles encourage design for recyclability, with specifications that facilitate separation and processing in standard recycling streams.

Bio-based adhesives and water-based inks support environmental objectives while maintaining the structural integrity and visual appeal of industrial cardboard box solutions. The elimination of plastic components and non-recyclable materials enhances the overall sustainability profile of packaging systems. Life cycle assessment methodologies help industrial buyers evaluate the environmental impact of different cardboard box specifications throughout the entire product lifecycle from raw material extraction through end-of-life disposal or recycling.

Carbon Footprint and Transportation Efficiency

Transportation efficiency directly correlates with cardboard box design optimization and material usage. Lightweight corrugated constructions reduce shipping weights and associated carbon emissions while maintaining protective capabilities. Nested or collapsible box designs minimize storage space requirements and reduce transportation costs for empty packaging materials. The optimization of box dimensions for standard shipping containers maximizes load efficiency and reduces the number of shipments required for equivalent product volumes.

Regional sourcing of cardboard box materials reduces transportation distances and supports local manufacturing capabilities. Industrial buyers increasingly specify locally-produced corrugated materials to minimize supply chain complexity and environmental impact. The integration of renewable energy sources in corrugated manufacturing facilities becomes a specification consideration for companies with comprehensive sustainability commitments across their supply chain operations.

Quality Control and Testing Protocols

Performance Testing Standards

Comprehensive testing protocols ensure that cardboard box specifications translate into consistent performance across production volumes. Edge crush testing, box compression testing, and vibration analysis simulate real-world shipping conditions to validate packaging design effectiveness. Drop testing from various heights and orientations identifies potential failure modes and guides structural reinforcement requirements. Environmental conditioning tests expose cardboard box samples to temperature and humidity variations that may occur during transportation and storage.

Statistical quality control procedures monitor key performance indicators throughout production runs to maintain specification compliance. Sampling protocols define inspection frequencies and acceptance criteria for dimensional tolerances, print quality, and structural properties. Documentation requirements ensure traceability and provide evidence of compliance with customer specifications and regulatory standards. Continuous improvement processes use quality data to optimize cardboard box designs and manufacturing parameters over time.

Incoming Material Inspection

Raw material quality directly impacts the performance of finished cardboard box products, requiring comprehensive incoming inspection procedures. Corrugated board properties including thickness, moisture content, and adhesive bond strength must meet specified tolerances before processing begins. Print substrate characteristics affect graphic reproduction quality and require evaluation against established standards. The verification of recycled content levels and environmental certifications ensures compliance with sustainability requirements specified by industrial customers.

Supplier qualification processes evaluate the capability of corrugated manufacturers to consistently meet cardboard box specifications across extended production periods. Quality agreements define testing procedures, documentation requirements, and corrective action protocols for non-conforming materials. Regular audits of supplier facilities ensure continued compliance with quality standards and environmental regulations throughout the supply relationship.

Cost Optimization Strategies

Material Efficiency and Waste Reduction

Efficient cardboard box design minimizes material usage while maintaining protective performance and regulatory compliance. Computer-aided design tools optimize corrugated sheet layouts to reduce trim waste and maximize material utilization. Standardization of box dimensions across product lines enables volume purchasing advantages and simplifies inventory management. The selection of appropriate corrugated grades balances performance requirements with material costs to achieve optimal value propositions.

Manufacturing efficiency improvements reduce conversion costs and improve delivery reliability for industrial cardboard box requirements. High-speed die-cutting equipment and automated folding systems increase production capacity while maintaining dimensional accuracy. Lean manufacturing principles eliminate waste in setup times, material handling, and quality inspection processes. The integration of digital workflow systems streamlines order processing and reduces administrative costs throughout the supply chain.

Volume Procurement and Supply Chain Management

Strategic procurement approaches leverage volume commitments to secure favorable pricing for cardboard box specifications while maintaining supply flexibility. Annual supply agreements provide price stability and guaranteed capacity allocation during peak demand periods. Multi-supplier strategies reduce supply risk while enabling competitive bidding processes that drive continuous cost improvements. Regional supplier networks minimize transportation costs and provide backup capacity for critical packaging requirements.

Inventory optimization balances carrying costs against procurement savings and supply security considerations. Just-in-time delivery programs reduce warehouse space requirements while maintaining production continuity. Collaborative forecasting with suppliers improves demand visibility and enables more efficient production planning. The implementation of vendor-managed inventory programs transfers inventory carrying costs to suppliers while ensuring material availability for production schedules.

FAQ

What edge crush strength should I specify for my industrial cardboard box application

Edge crush strength requirements depend on your product weight, stacking height, and storage duration. For products under 20 pounds with minimal stacking, 32 ECT provides adequate performance. Medium-weight applications between 20-50 pounds typically require 44-48 ECT, while heavy industrial products over 50 pounds need 61-71 ECT ratings. Consider your maximum pallet stacking height and warehouse storage conditions when determining the appropriate ECT specification for your cardboard box requirements.

How do I determine the optimal dimensions for my cardboard box specification

Start with your product dimensions and add 1-2 inches on each side for protective cushioning materials. Consider standard pallet sizes to maximize shipping efficiency - North American 48x40 pallets or European 1200x800mm pallets. Ensure your box configuration creates stable pallet patterns and fits within shipping container constraints. Factor in automated handling requirements if your boxes will move through conveyor systems or robotic picking operations during distribution.

What printing capabilities should I include in my cardboard box specification

Flexographic printing handles most industrial requirements with up to six colors and good registration for logos and regulatory markings. Digital printing offers variable data capabilities for serialization and customization but may have volume limitations. Consider your color accuracy requirements, with pre-print processes providing superior quality for complex graphics. Include specifications for regulatory markings, compliance information, and any required multilingual text for international shipping applications.

How can I balance environmental sustainability with performance in my cardboard box specification

Specify high recycled content levels while maintaining required strength properties - many applications can use 70-90% post-consumer recycled fiber without performance compromise. Choose water-based inks and bio-based adhesives to enhance recyclability. Design boxes for efficient transportation and storage to minimize carbon footprint. Consider regional sourcing to reduce transportation distances and work with suppliers who use renewable energy in their manufacturing processes.

Table of Contents

- Material Specifications and Corrugated Construction

- Dimensional Engineering and Load Distribution

- Printing and Branding Requirements

- Environmental Considerations and Sustainability

- Quality Control and Testing Protocols

- Cost Optimization Strategies

-

FAQ

- What edge crush strength should I specify for my industrial cardboard box application

- How do I determine the optimal dimensions for my cardboard box specification

- What printing capabilities should I include in my cardboard box specification

- How can I balance environmental sustainability with performance in my cardboard box specification