custom cardboard packaging

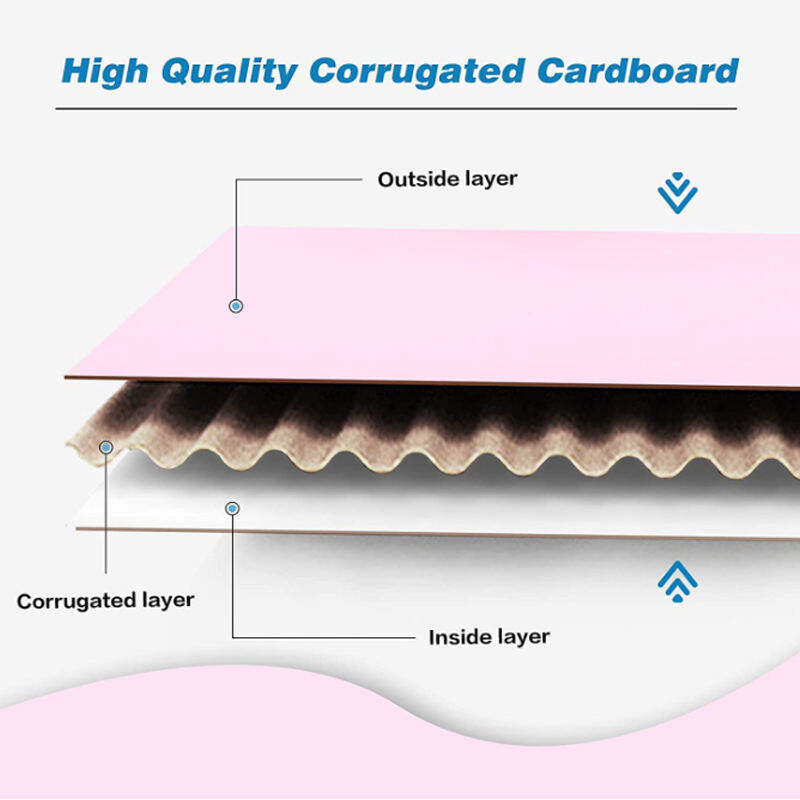

Custom cardboard packaging represents a versatile and sustainable solution for modern business needs, combining practical functionality with environmental responsibility. These packaging solutions are engineered using high-quality corrugated materials that provide exceptional protection for products during storage and transportation. The manufacturing process involves advanced die-cutting technology and precision folding techniques, ensuring each package meets exact specifications. The structural design incorporates multiple layers of fluting, which creates a robust cushioning effect while maintaining a lightweight profile. These packages can be customized in terms of size, shape, strength, and printing options, accommodating various product dimensions and branding requirements. The materials used are specifically selected for their durability and recyclability, featuring water-resistant coatings when needed and reinforced corners for enhanced protection. Modern custom cardboard packaging also integrates smart features such as easy-assembly mechanisms, tamper-evident seals, and specialized inserts for product organization. The printing capabilities extend to high-resolution graphics, custom branding elements, and protective coatings that preserve the visual appeal throughout the supply chain.